The specialty of these heaters lies in its external stricture. The flat shape of heaters gives them a flexibility to be used with more comfort. They look like a new-age product. There are several advanced features incorporated in these heaters making them better than general heaters

Ceramic Flat Infrared Heaters are constructed by a firmly burnt-in heating coil. They consist of high heatproof resistant wire.

We make available this type of heater in standard size of

| Type // Weight g // Wattage W | FSF/1 FSF | 220 | 250 | 400 | 600 | 800 | 1000 |

|---|---|---|---|---|---|---|---|

| FSF/2 | 125 | 125 | 200 | 300 | 400 | 500 | |

| FSF/4 | 75 | 60 | 100 | 150 | 200 | 250 | |

| Surface rating | kW/m² | 16,0 | 25,6 | 38,4 | 51,2 | 64,0 | |

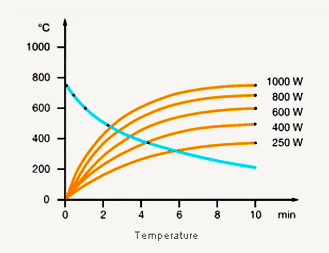

| Typical operating temperature | °C | 400 | 500 | 590 | 670 | 720 | |

| Maximum permissible temperature | °C | 750 | 750 | 750 | 750 | 750 | |

| Wavelength range | µm | 2 - 10 | |||||

| Standard Design | Thermocouple Heater | Variants |

|---|---|---|

| operating voltage 230 V | integrated thermocouple type K (NiCr-Ni) | special wattages |

| ceramic full-pour casting | description T-FSR // T-FSR/2 // T-FSR/4 | special voltages |

| leads 85 mm | TC leads 100 mm | extended leads |

| Elstein standard socket | power leads with ring terminals | |

| mounting set |

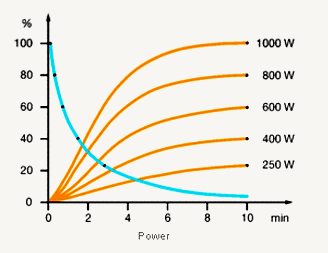

The power can be controlled by using thermocouple heaters with TRD temperature controllers, TSE thyristor switching units and other accessories.

IR radiation panels can be assembled using mounting sheets MBO.

The national safety regulations must be complied with for the respective application, for example, the IEC or EN standard 60519-1, Safety in electrical heating installations.

Further information and safety instructions are mentioned in the mounting sheet, which is attached to each heater.