Elstein Infrared Heaters are designed to produce maximum output in form of heat energy. They are constructed by a firmly burnt-in heating coil. The heater incorporates highly heatproof resistance wire that provides safety against any damage. We supply Custom Wattage Infrared Ceramic Heaters as per the requirement of our clients.

Longer service life is achieved since the resistance of the heaters is made to remain constant over the whole temperature range. The glaze used in this heater has excellent radiation properties therefore the radiation efficiency is also very high. This heater is available with Color Changing Feature as Yellow Ceramic IR Heater (CC FSR).

Our Ceramic Infrared Heaters are available in 3 standard models:

| Type // Weight g // Wattage W | FSR | 220 | 250 | 400 | 650 | 1000 |

| FSR/2 | 125 | 125 | 200 | 325 | 500 | |

| FSR/4 | 75 | 60 | 100 | 200 | 250 | |

| Surface rating | kW/ m² | 16,0 | 25,6 | 41,6 | 64,0 | |

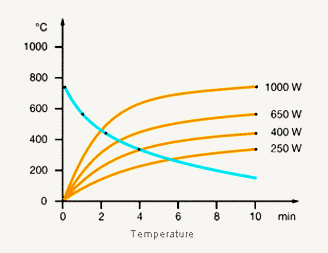

| Typical operating temperature | °C | 400 | 500 | 620 | 720 | |

| Maximum permissible temperature | °C | 750 | 750 | 750 | 750 | |

| Wavelength range | µm | 2 - 10 | ||||

| Standard Design | Variants | Variants |

|---|---|---|

| operating voltage 230 V | integrated thermocouple type K (NiCr-Ni) | special wattages |

| ceramic full-pour casting | description T-FSR // T-FSR/2 // T-FSR/4 | special voltages |

| leads 85 mm | TC leads 100 mm | extended leads |

| Elstein standard socket | power leads with ring terminals | |

| mounting set |

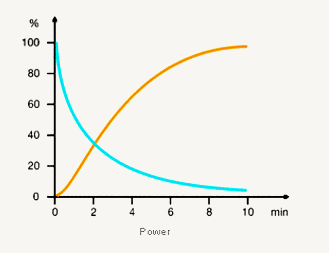

The power can be controlled by using thermocouple heaters with TRD temperature controllers, TSE thyristor switching units and other accessories.

IR radiation panels can be assembled using REO reflectors, REF construction sets, EBI and EBF construction elements as well as mounting sheets MBO.

The national safety regulations must be complied with for the respective application, for example, the IEC or EN standard 60519-1, Safety in electrical heating installations.

Further information and safety instructions are mentioned in the mounting sheet, which is attached to each heater.